Home > Service > Livestock and Poultry Feed Machinery > Gear Pellet Mill

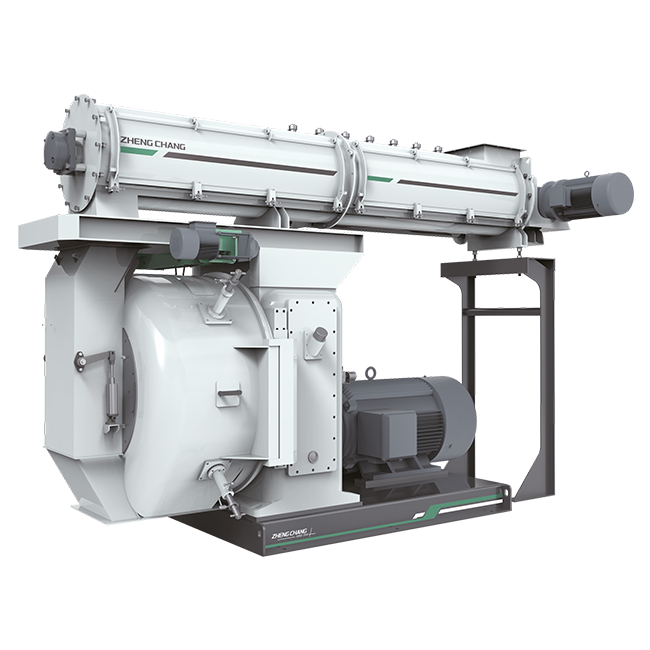

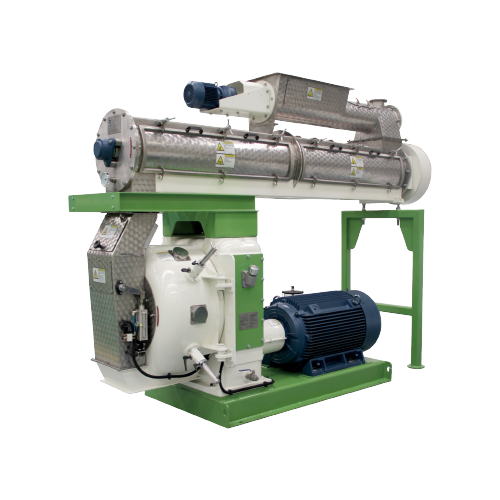

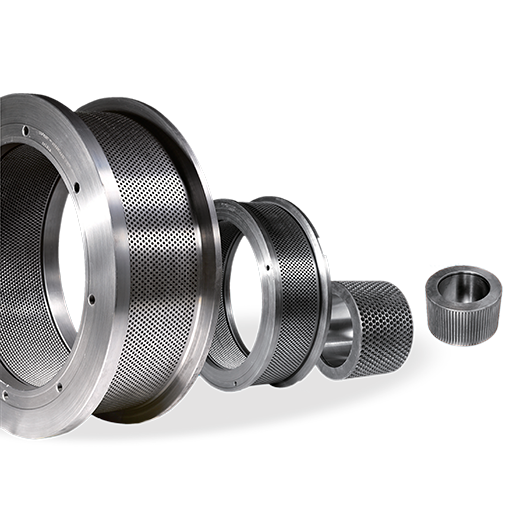

Gear Pellet Mill

Gear Pellet Mill

• Higher speed and stronger conditioner: Extended stainless steel conditioner with better design of conditioner blade and speed, which makes the materials cooked fully.

• Up to more than 10 years of service life: The box adopts American special casting technology and the standard parts are all imported.

• 15% higher production efficiency: Adopted American and European gear type drive system, higher transmission efficiency.

• Full range of after-sales: Fast and thoughtful on-site service; prompt quality replacement of wearing parts.

• More professional models to support the sustainable development for customers: Relying on several decades of professional pellet mill production technology, Zhengchang has developed dozens of professional pellet mills for poultry, aquatic, forage, and so on for users’ choices.

• Higher feed quality: Feed produced by Zhengchang’s new type pellet mill has good appearance and same length, cleaner and healthier.

• High-precision gear drive, imported SKG or NSK bearing, 20% higher efficiency.

Gear Pellet Mill Features

| Type | Main Power(kW) | Production Capacity(t/h) | Feeder Power(kW) | Conditioner Power(kW) | Die Diameter(mm) | Pellet Size(mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SZLH 200 | SZLH 25 | SZLH 30 | KYW 32a | SZLH 350 | SZLH 350D | SZLH 400D | SZLH 420D | SZLH 428 | SZLH 508H | SZLH 558E | SZLH 678D | SZLH 768 | SZLH 858 | SZLH 968 | SZLH 1068 | SZLH 1208 |

| 5.5 | 15 | 22/30 | 37 | 55 | 55 | 75/90 | 110 | 110/132 | 132/160 | 185/200 | 220/250 | 250/280 | 315/355 | 355/400 | 355/400/450 | 500/560/630 |

| 0.05-0.25 | 0.5-1.5 | 1-4 | 3-5 | 3-7 | 4-8 | 5-12 | 6-15 | 8-18 | 6-20 | 12-26 | 15-33 | 18-35 | 25-45 | 35-50 | 45-55 | 55-75 |

| 0.25 | 0.75 | 0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 4 | 4 | 4 |

| 1.5 | 2.2 | 2.2 | 3 | 3 | 3 | 5.5 | 5.5 | 11 | 11 | 11 | 15 | 15 | 15+22 | 15+22 | 15+22 | 22+37 |

| 200 | 250 | 300 | 320 | 350 | 320 | 400 | 420 | 460 | 508 | 572 | 673 | 762 | 858 | 968 | 1068 | 1208 |

| Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 | Φ2-Φ12 |

Fertilizer pellet Mill Features

| Type | Main Power (KW) | Capacity (t/h) | ||

|---|---|---|---|---|

| FZLH 32 | FZLH 350 | FZLH 420 | FZLH 508 | FZLH 768 |

| 37 | 55 | 110 | 160 | 250 |

| 1.5-2 | 2.5-3 | 4.5-5 | 5.5-6 | 10-11 |

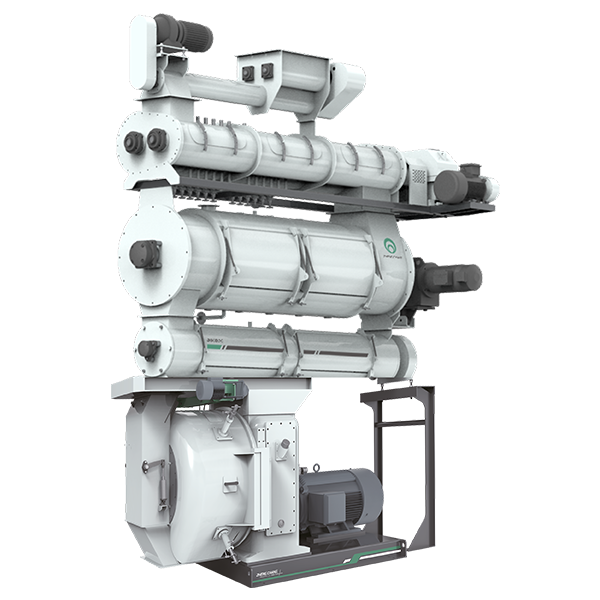

The largest output pellet mill in China with the capacity of 55-75 t/h

● Production up to 55-75t/h, main power 500/560/630k.

● Bearing temperature measuring device can monitor the temperature of key bearing in real time, and can judge the early failure of the bearing by temperature, so as to ensure the safe and efficient operation of the equipment.

● Oil cooling lubricating system can circularly cool the oil temperature and the key bearing of the machine.

● Automatic oil lubrication system can be used to add oil on a regular basis, reducing the workload of operators and make the equipment more reliable.

● The electric ring die lifting device improves the assembly efficiency of the ring die and roller, and reduces the labor intensity.

● The electric cutting adjusting mechanism improves the accuracy of clearance adjustment by operation screen.

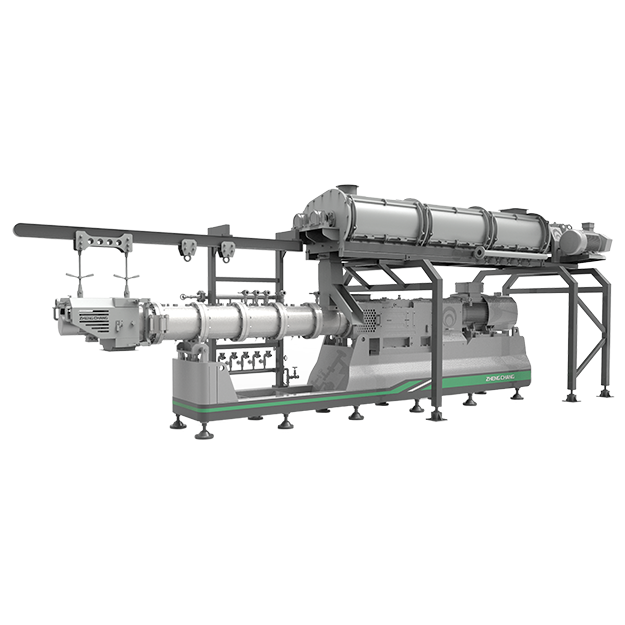

Fertilizer Pellet Mill

The equipment is adopt to organic compound fertilizer production, based on main material as chicken manure, cow, cattle and sheep manure etc. With ZHENGCHANG special designed procession fermentation, drying, crushing, mixing and pelleting, it can supply you high-quality fertilizer. This kind of fertilizer has the following advantages: no foul smell, no pollution, easy for transportation and storage, beneficial to the absorption of plants.