Sama Gostar Kohan the exclusive agent of Alberk company can provide high quality poultry processing equipment for its customers which ensures a sanitary and efficient slaughtering process.

Livestock arrival department is the first section in poultry processing. The poultry will be transferred in cases to the slaughterhouse. In this section we have a "livestock case transferring belt conveyor" and a "case washing machine". The equipment will be selected according to the capacity of the facility. For more details click here.

view Livestock Arrival Department

Slaughtering the poultry, plucking their feathers, and preparing them for evisceration process is the main task of this section. Therefore, the functionality of the machines is very important. These processes are performed by using various machines and equipment. The modular structure of the line allows easy solutions for potential capacity upgrades in the future. Thus, it offers an opportunity for modifications in the existing system. Also many safety measures are taken in this section and an efficient, fast and eco-friendly operation is ensured. For more details click here.

view Killing and Defeathering

The automatic evisceration department includes the most complicated equipment and machinery. The internal organs of poultry will be extracted in this section. The machinery are vent cutter, opening machine, evisceration machine, evisceration belt, automatic gizzard cleaning machine,.... For more details click here.

view Automatic Evisceration Department

Washing and cooling are very important steps in poultry processing. The main goal in this section is decreasing the poultry temperature after slaughtering and evisceration section and before the air cooling process. This will ensure product quality and its shelf life. For more details click here.

view Water Washing and Chilling Department

In poultry processing, air chilling section has a direct impact on the product, it is essential for the poultry health and requires extreme care. The duration of keeping the product in the cool air chamber and the chamber's temperature is substantial. For more details click here.

view Air Chilling Department

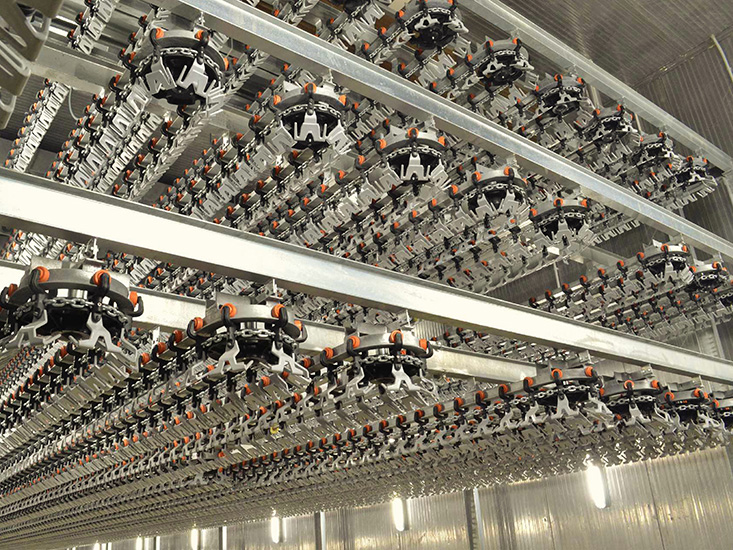

This is the most electronically complex section. In this section, the weight and quality of the product is automatically determined using the computer software in the weighing and sorting line panel. The PLC system weighs the products and sends the data to the computer program. ALBERK weighing and sorting line is very accurate despite the high rate of rotation of the conveyor lines. For more details click here.

view Weighing and Sorting Department

Packaging is the last stage in poultry processing. The products will be packed with pneumatic bagging machine and the clipping machine which are mounted on the belt. For more details click here.

view Packaging Group

The cut up process is performed by machines which are installed on the line but operates independently from one an other. The cut up line consists of wing tip cutter, whole wing cutter, breast cap cutter and special breast cutter, splitting into two, drumstick cutting and dropping machines. The line has a modular structure, and machines can be easily added or removed. For more details click here.

view Cut-up Department

The poultry processing results in various types of waste and garbage and it should be under control. The "Waste Separator" and "Pump Group" is used to evaluate such waste in the facilities. It must be noted that the cleanliness of the facility from live entrance to product shipping is paramount and it should be considered in the slaughterhouse designing in the first place. For more details click here.

view Waste System

Control system panels are responsible for the control, management, safety and supplying main power of all equipment in the poultry process.

view Control System Panels•

ALBERK was founded in 1995 to meet the needs of the Poultry sector. With decades of know-how, ALBERK has become a globally recognized, well-known and prestigious company in this sector through its projects which has established them in more than 30 countries.

As global population growth rates increased, the importance of the food production sector, especially the poultry sector, increased. As a result of the technological and mechanical innovations, the slaughterhouse process has developed and changed as well as all other sectors. By keeping up with these developments and changes, ALBERK has continued and will continue to work to meet all the needs of customers.