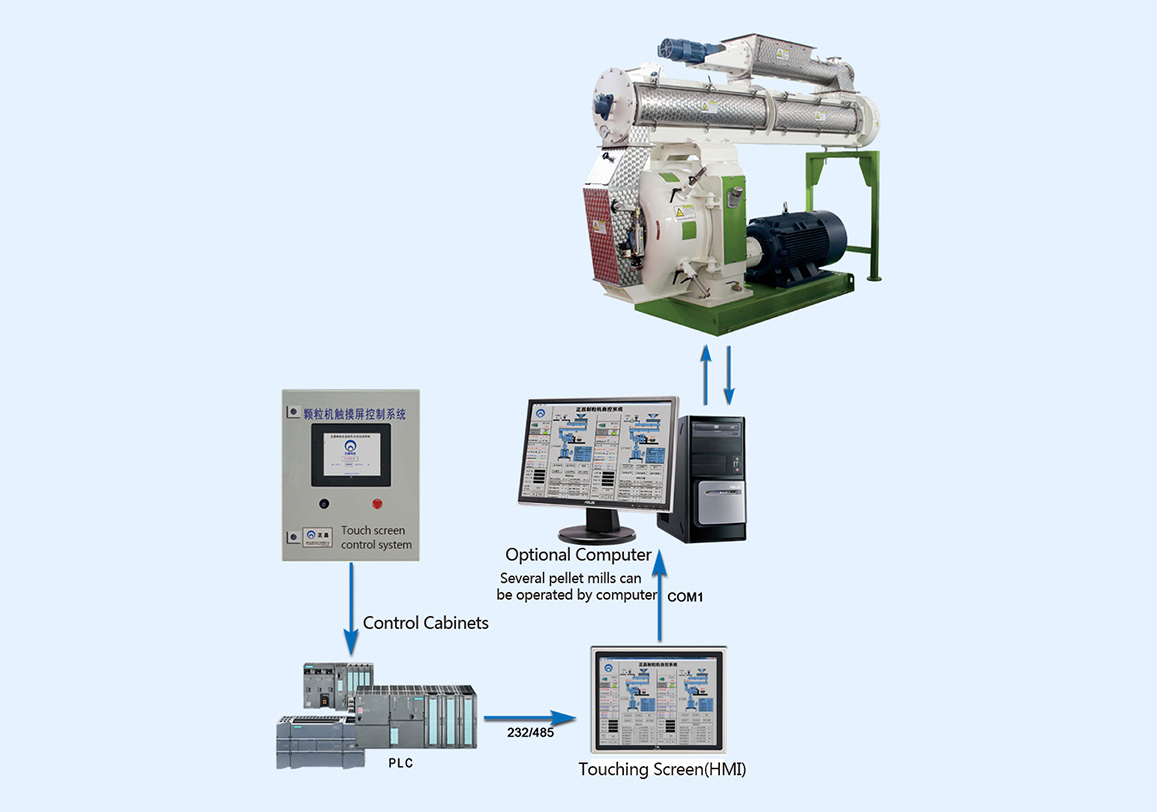

Zhengchang Feed Quality Optimization System integrates two core values for all the customers:

• The automatic operation of Pellet Mill

• The Feed Optimization of Feed Quality

•

Nowadays, the qualified and skilled operator of Pellet mill is more and more difficult to be found. Many of the pellet mills can not be operated with the highest capacity and with the best condition. The capacity of the pellet mill sometimes only can reach 50-60% of the standard level. It also takes a long time for the operator to adjust the frequency of the feeder and the volume of steam. Even the moisture of the pellet can not be controlled. A lot of money is lost during operation.

•

•

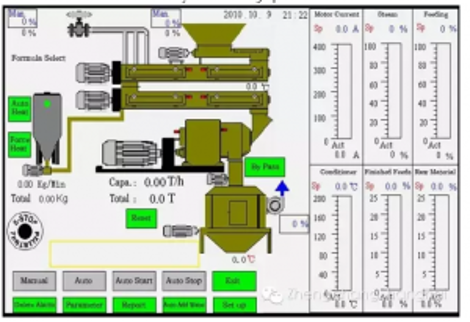

Zhechang Feed Quality Optimization System can help to solve this problem completely. The system can be adjusted and set according to different formulation and feed of the customers. The system can automatically operate the pellet mill, and push to the highest capacity through the adjusting of Feeding Frequency, volume of steam, conditioning temperature, etc. The current of the main motor of the pellet mill can reach about 90% of the rated current.

•

•

Even it can only increase 10% capacity of your pellet mill, it is easy to calculate how much profit this system can bring you. In fact, the capacity can be increased more than 20%, if you do not have a qualified operator.

•

The another powerful function of this system is the control and adjusting of the moisture of the feed. Sensors of moisture detecting are installed before and after pelleting.

As we know, the moisture of the feed can not be too high and also can not be too low. If too high, it will affect the quality of the feed. If the moisture is too low, each point of moisture lower than the standard requirement is the lose of your profit. Also the low moisture will also affect the capacity of pelleting.

•

•

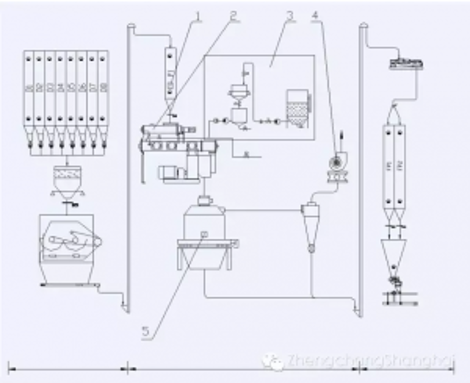

The system include the following checking points as shown in the above map:

1. Moisture sensor checks mash moisture before pelleting,

2. Pellet mill with steam adding are automatically controlled,

3. Water adding system to conditioner,

4. VFD controlled fan drive, controlling fan speed and moisture,

5. Moisture sensor checking finished products continuously

•