Home > Service > Livestock and Poultry Feed Machinery > Ring Die and Roller

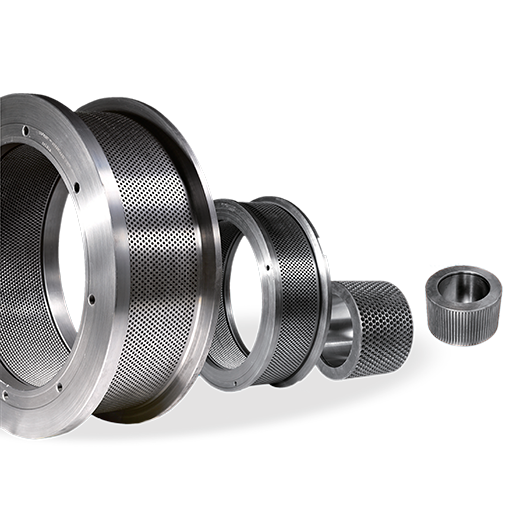

Ring Die and Roller

Ring Die and Roller

Zheng Chang’s Die Advantages

● Quality forging material are selected, while other companies select casting material.

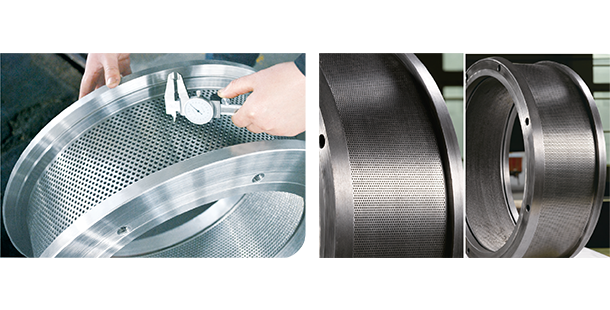

● It uses imported gun drill and multiple drills, the hole is formed at one time with high smoothness, beautiful appearance and high output.

● American vacuum oven and continuous quenching furnace to ensure the service life is doubled.

● Strong R&D helps customers to design compression ratio and strength according to unique requirements, to ensure the discharging and pellet appearance.

Zheng Chang 21 Steps of Die Manufacturing

1. Qualified blank acceptance 12. Finish turning

2. Tempering 13. Flange assembling

3. Semi finish turning 14. Finish turning again

4. Seal line 15. Bore-hole repairing

5. Holes drilling 16. Grinding using bran

6. Holes patching 17. Cleaning the bran

7. Counter sinking 18. Abrasive blasting

8. Counter bore 19. Hard waste and cleaning

9. key seat 20. Final inspection

10. Drill screw 21. Packing

11. Quenching