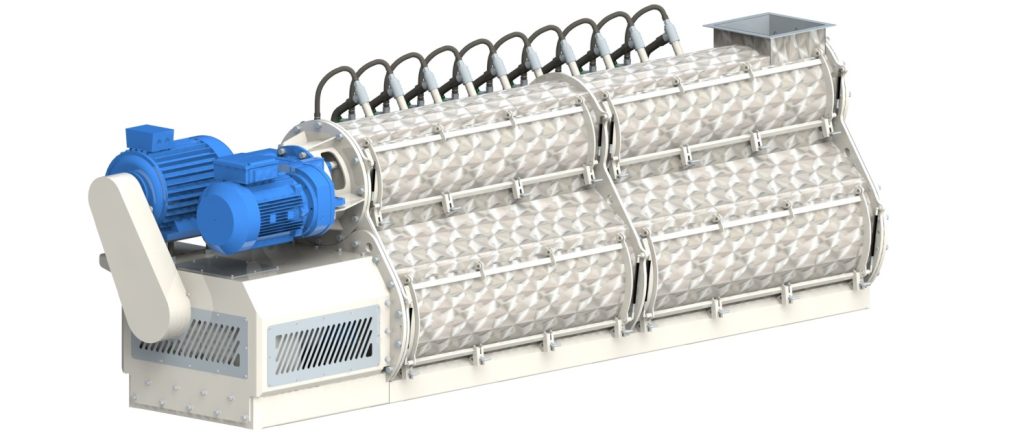

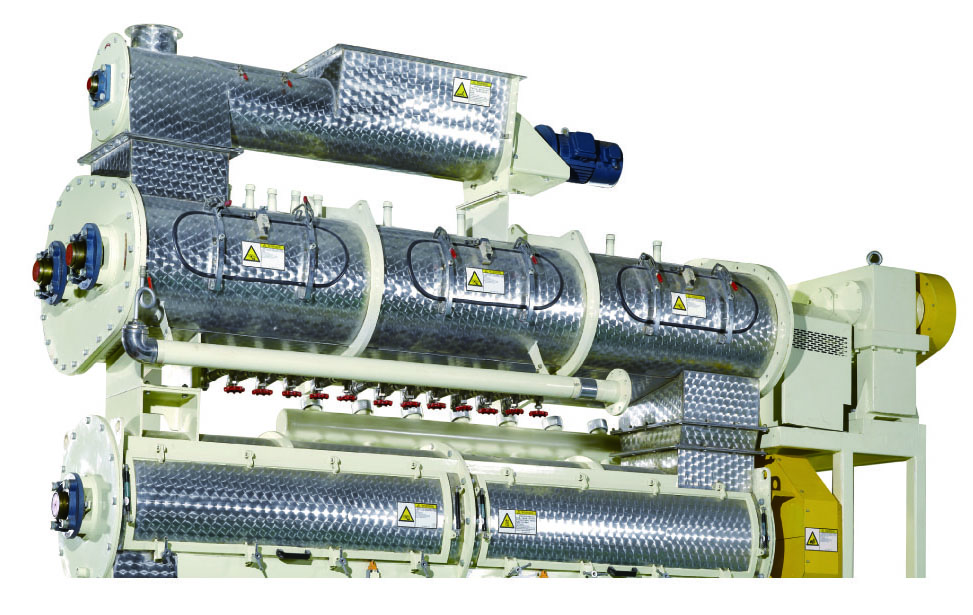

Conditioning is a process of hydrothermal treatment of powdery materials before pelleting of pellet feed. Domestic and foreign studies show that conditioning is one of the important factors affecting the quality of pellet feed, and it accounts for about 20% in the overall quality of pellet feed. With the improvement of the market requirements for the quality of pellet feed machine, feed processing enterprises pay more and more attention to the conditioning process in feed processing. Improving and upgrading the conditioning equipment is one of the important means to improve the quality of pellet feed products and enhance the market competitiveness.

•

•

The powder material can be matured by conditioning. Most animals have low ability to digest starch, but they can digest ripe starch to a large extent. The gelatinization degree of starch increases greatly under the action of hydrothermal by conditioner. At the same time, it promotes the thermal denaturation of protein in the material. The denatured protein is easy to be enzymatically hydrolyzed, which improves the digestion efficiency of pellet feed. The powder material can be sterilized by conditioning. Most pathogenic bacteria such as Escherichia coli and Salmonella are not heat-resistant. Conditioning materials at a certain temperature can kill these pathogens and ensure the level of feed hygiene. This method has the advantages of low cost, pollution-free, no drug residue and side effects compared with drug disease prevention.

•

•

Conditioning equipment can significantly improve the water resistance of pellet feed. In the process of conditioning, through the hydrothermal effect of steam, the viscous component like gelatinized starch and denatured protein in the material of pellet feed machine can fully exert the role of binder, and can effectively bond other components around. Under the extrusion effect of ring die and roller, particles combine more closely with each other, which makes the pellet feed denser and cleaner, and is not easily eroded by water during feeding, thus increasing the stability in water.

•

•

The conditioning equipment can improve the pelleting effect of material, increase the output, save the energy consumption and improve the service life of ring die and roller of pellet mil. Materials can be softened and more plasticity by conditioning. In the extrusion process with the hole wall, the inner wall of ring die and the exterior of roller, the friction force decreases, avoiding the transformation of a large amount of mechanical energy into heat energy in pelleting process, and reduces the abrasion of ring die and roller.