Home > Service > Livestock and Poultry Feed Machinery > Mixer

Mixer

Mixer

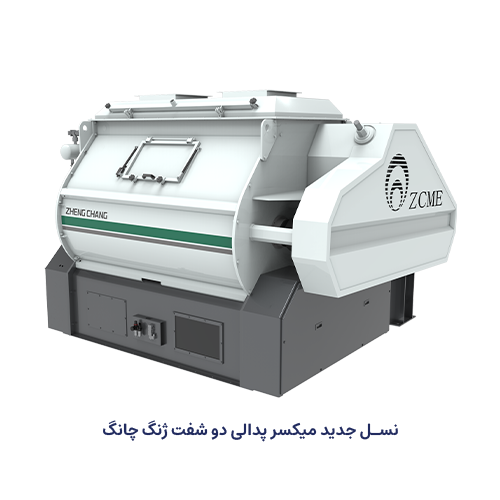

• The new type mixer adopted Forberg technology, CV<5%, can reach 2.3% mixing evenness in 30 seconds, greatly improves the value of the mixer.

• The special design of double reducer ensures efficient power transmission, and save energy.

• The improvement on door shaft and the connecting rod ensures the door opening angle bigger than 90° (feed does not fall on the door).

• The improvement on the discharge door structure increases the sealing surface which ensures better sealing without leakage.

• The unique design of the return air system ensures steady air flow during the feeding process.

• Advanced adding and spraying system can add a variety of liquid and spray with accuracy and convenient control.

• Faster discharging, less residual; adopted Forberg technology, more durable;

• Double speed reducer with belt drive, transmits smoothly, can save 20% power than chain transmission.

• Low wearing of the belt, easy to maintain and repair.

• Materials are mixed in zero gravity, and not affected by material particle size, density or other factors.

• It has high mixing uniformity, short mixing time, no dead corner. Each batch will be mixed evenly in 30-120 seconds.

• The feed discharge adopted full length door structure, which discharges quickly, low residue.

• It has wider range of loading capacity. There are oil adding pipelines in the machine, which can take a variety of liquid.

• The machine structure is compact with good shape and covers an area of space less than other mixing equipment.

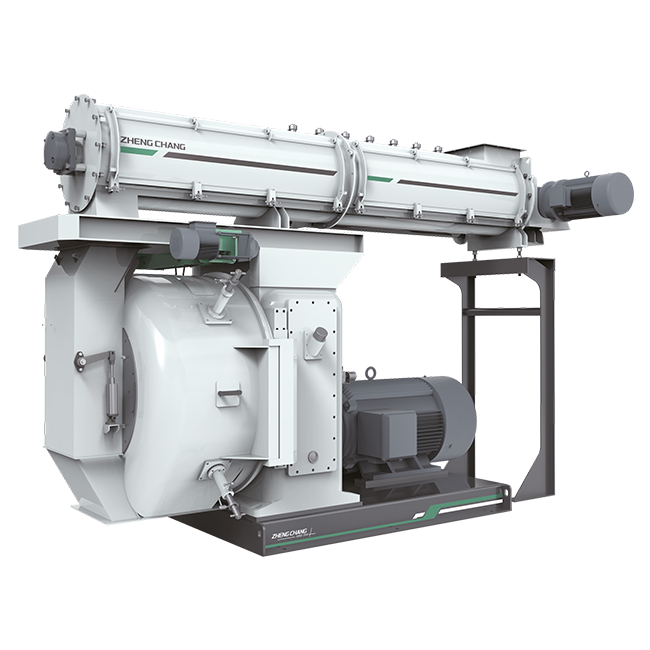

Double-shaft Mixer Features

| Type | Effective Volume(m3) | Mixing Amount per Batch(kg) | Mixing Time per Batch(s) | Mixing Uniformity(Cv%≤) | Power(kW) | Speed(rpm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SSHJ 0.2d | SSHJ 0.5da | SSHJ 1da | SSHJ 2da | SSHJ 3da | SSHJ 4da | SSHJ 6da | SSHJ 8d | SSHJ 4Sa | SSHJ 6Sb | SSHJ 8s | SSHJ 10s |

| 0.2 | 0.5 | 1 | 2 | 3 | 4 | 6 | 8 | 4 | 6 | 8 | 10 |

| 100 | 250 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 2000 | 3000 | 4000 | 5000 |

| 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 |

| 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| 3 | 7.5 | 15 | 18.5 | 22 | 30 | 37 | 45 | 22 | 37 | 45 | 75 |

| 35 | 50 | 50 | 35 | 31 | 30 | 24 | 21 | 30 | 25 | 21 | 18 |

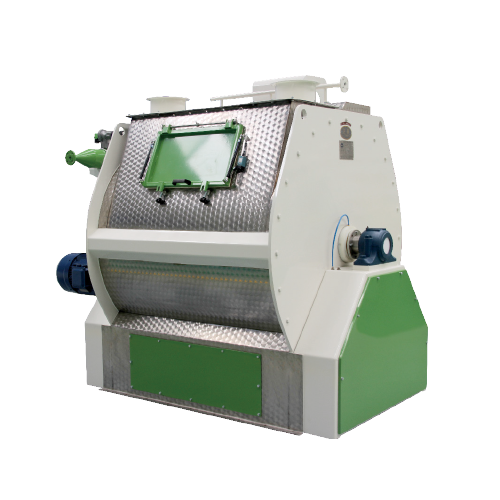

Single-shaft Mixer Features

| Type | Effective Volume(m3) | Mixing Amount per Batch(kg) | Mixing Time per Batch(s) | Mixing Uniformity(Cv%≤) | Power(kW) | Speed(rpm) |

|---|---|---|---|---|---|---|

| SDHJ 1b | SDHJ 2b | SDHJ 3b | SDHJ 4b | SDHJ 6b | SDHJ 10b | SDHJ 12b |

| 1 | 2 | 3 | 4 | 6 | 10 | 12 |

| 500 | 1000 | 1500 | 2000 | 3000 | 5000 | 6000 |

| 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 | 60-120 |

| 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| 11 | 18.5 | 22 | 30 | 30×2 | 37×2 | 45×2 |

| 43 | 39 | 30 | 28 | 28 | 24 | 24 |

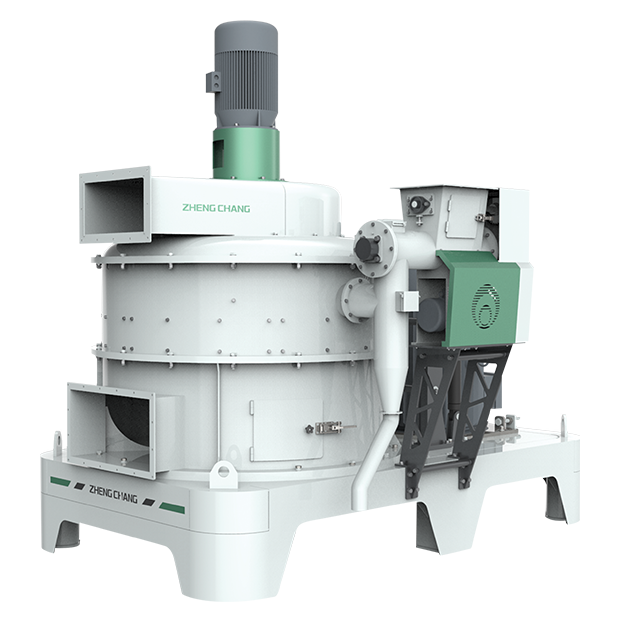

Ribbon-Spiral Mixer

| Type | Effective Volume(m3) | Mixing Amount per Batch(kg) | Mixing Time per Batch(s) | Mixing Uniformity(Cv%≤) | Power(kW) | Speed(rpm) | |

|---|---|---|---|---|---|---|---|

| SLHY 0.4a | SLHY 0.6 | SLHY 1c | SLHY 2.5 | SLHY 5 | SLHY 7.5 | SLHY 10 | SLHY 12 |

| 0.4 | 0.6 | 1 | 2.5 | 5 | 7.5 | 10 | 12 |

| 200 | 300 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 |

| 3-6 | 3-6 | 3-6 | 3-6 | 3-6 | 3-6 | 3-6 | 3-6 |

| 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| 4 | 5.5 | 11 | 18.5 | 30 | 37 | 45 | 75 |

| 35 | 34 | 32 | 30 | 28.8 | 26 | 22 | 21 |