Home > Service > Livestock and Poultry Feed Machinery > Hammer Mill

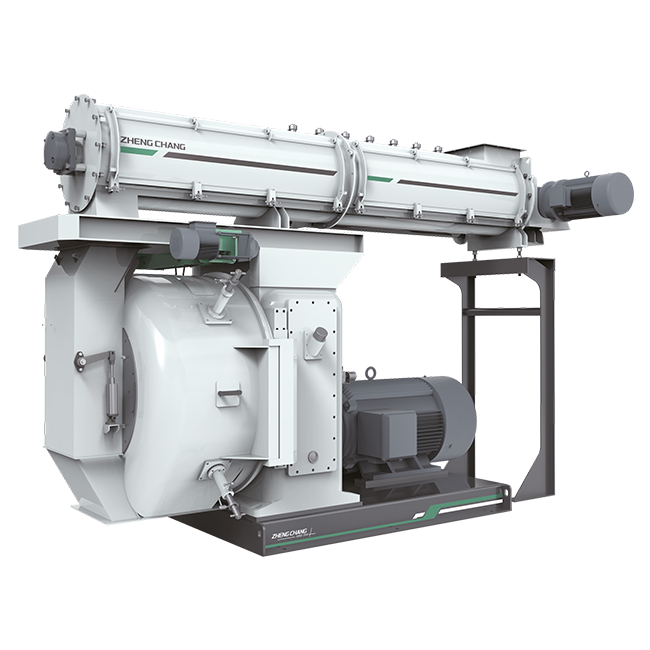

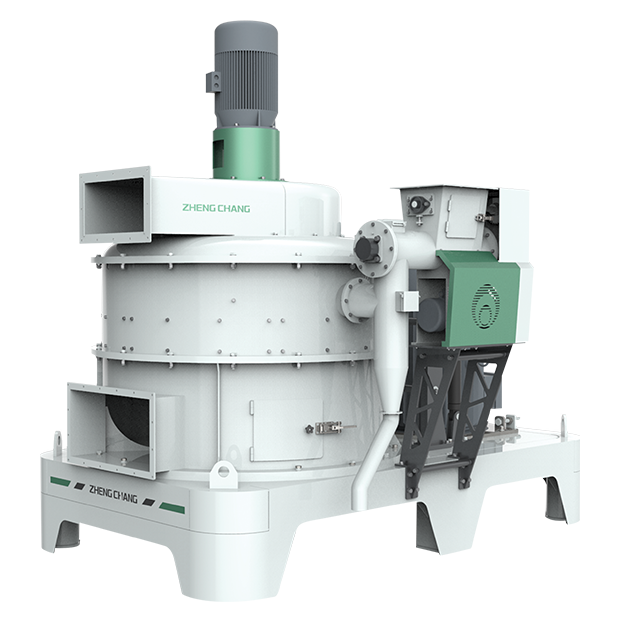

Hammer Mill

Hammer Mill

• First national patent in the industry.

• The crushing efficiency is improved by 30-50%, grinding fineness and uniformity is improved by more than 30%, crushing temperature is down by 0.5℃.

• It adopts high quality alloy hammer, which improves the efficiency by 50%.

138 Series Champion Hammer Mill Features

| Type | Main Power(kW) | Production Capacity(t/h)-Ø3mm | Production Capacity(t/h)-Ø1mm | |

|---|---|---|---|---|

| SFSP 138×38F | SFSP 138×50F | SFSP 138×60F | SFSP 138×75F | SFSP 138×100F |

| 90/110/132 | 132/160 | 160/200/220 | 200/220/250 | 250/280/315 |

| 15-30 | 22-35 | 27-48 | 33-55 | 41-70 |

| 4.5-8.8 | 7-11 | 8.5-15 | 11-18 | 13-21 |

112 Series Winner Hammer Mill Features

| Type | Main Power(kW) | Production Capacity(t/h)-Ø3mm | |||

|---|---|---|---|---|---|

| SFSP 112x30F | SFSP 112x38F | SFSP 112x50F | SFSP 112x60F | SFSP 112x75F | SFSP 112x100F |

| 55/75 | 90/110 | 110/132/160 | 160/200 | 200/220 | 220/250/280 |

| 10-15 | 15-20 | 19-26 | 28-36 | 33-50 | 36-62 |

72 Series Winner Hammer Mill Features

| Type | Main Power(kW) | Production Capacity(t/h)-Ø3mm | Production Capacity(t/h)-Ø1mm | ||

|---|---|---|---|---|---|

| SFSP 72x30F | SFSP 72x38F | SFSP 72x50F | SFSP 72x60F | SFSP 72x75F | SFSP 72x100F |

| 37/45 | 45/55 | 55/75 | 75/90/110 | 90/110/132 | 132/160 |

| 7-10 | 9-12 | 13-16 | 16-22 | 19-25 | 22-35 |

| 1.8-3.2 | 2.3-4 | 2.8-5 | 3.8-7 | 4.5-9 | 6.6-11 |

56 Series Winner Hammer Mill Features

| Type | Main Power(kW) | Production Capacity(t/h)-Ø3mm |

|---|---|---|

| SFSP 56x36a | SFSP 56x40a | |

| 22/30 | 30/37 | |

| 3-4/4-6 | 4-6/6-7 |

• The patent design prolongs the hammer sheet and plate life greatly, especially the life of the small aperture sieve-plate.

• The professional design of rotor assembly innovation makes rotor run more stably and the temperature of grinding chamber low even if the hammer is worn, professional design improves pressure sieve, makes it easy to fold and pack with more safety and reliability.

• The grinding load control device realized the close -loop control of load current and the feeding quantity which improved the grinding efficiency, and prevented from overload production.

• The close-loop chain control of main motor, pulse fan, and pulse electromagnetic valve ensures that the main motor and pulse fan will continue to work after the power is cut. It reduces the dust adsorption in the sack, which ensures the breathability of the pulse bag.

• The bag pulse blockage alarm system ensures the grinding chamber operates under negative pressure; main shaft temperature alarm system improved the stability of main drive.

• The grinding room is improved, grinding wind field is changed, the clashing space of material is enlarged, the running track of materials is changed, and the circulation of materials is broken, all of which improved the grinding efficiency; The design of machine base is improved; the welding deformation is reduced, which increases the working stability.

• The innovative design of fine grinding of fibrous material, high moisture, and oil big raw material is especially suitable for grinding of dried fish, cottonseed meal, corn on the cob, shrimp, bean curd, herbal materials and the highly moisture (17~24%) corn. It can work with full load, with no blocking sieve. When the grinding body works, the particles are more uniform. It can use large aperture screener with Ø1.2mm or below to produce coarse, medium, fine, superfine materials, with high efficiency and no paste sieve.