Home > Service > Aquatic Feed Machinery > Aquatic Feed Extruder

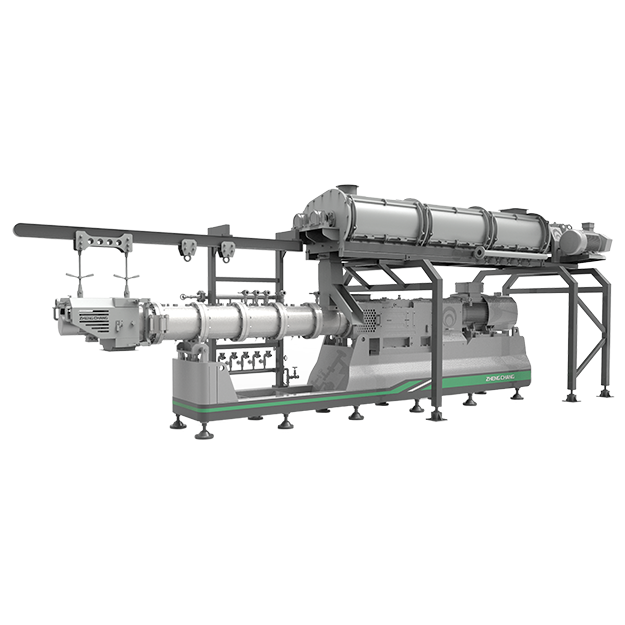

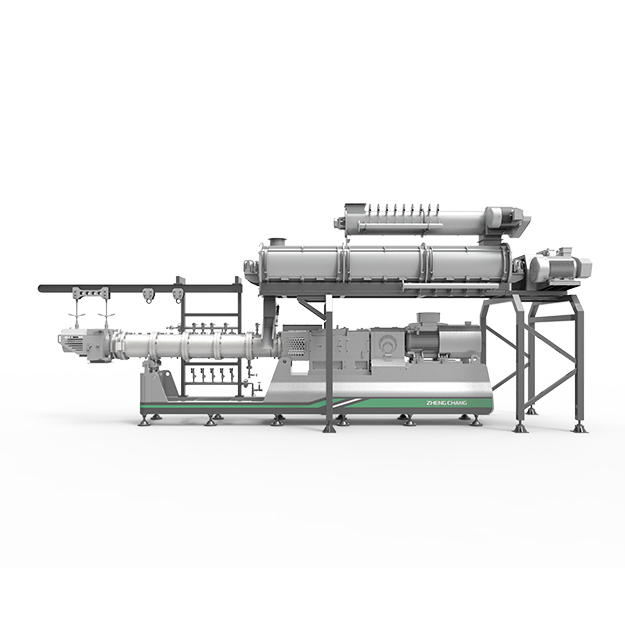

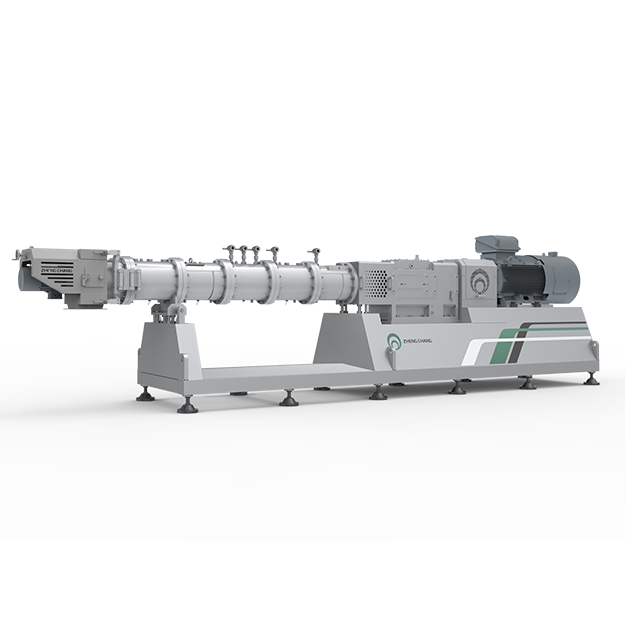

Aquatic Feed Extruder

Aquatic Feed Extruder

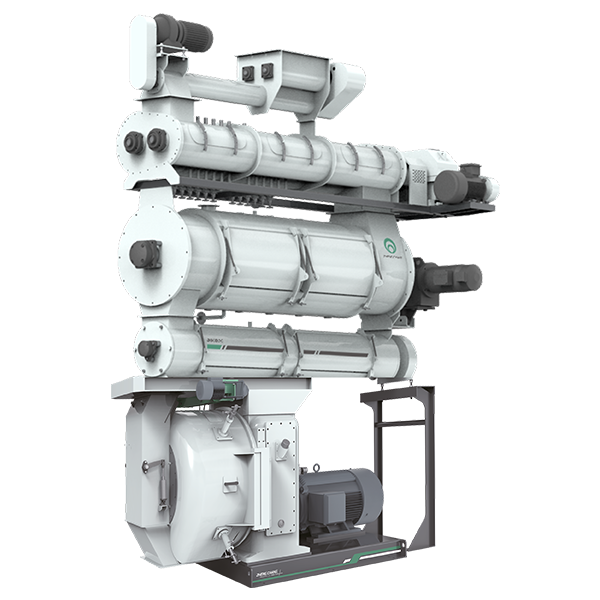

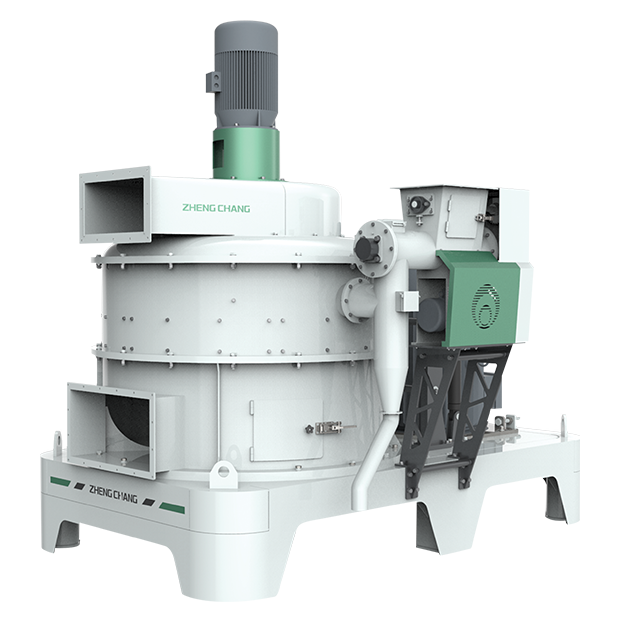

• It uses high-precision inverter, feeds more evenly than regular feeder, has high capacity, better stability and easy access.

• Quality feed: user-friendly design for steam and water injection, can detect the flow on-line and add liquid proportionally.

• Feed quality improvement: special design of mixing shaft and blade effectively improves maturity level and mixing evenness. It can add up to 30% water and steam which can be evenly mixed.

• Reduce the cost of consumable parts: it uses High hardness and wear-resistant alloy screws and bushings which greatly improves the service life of quick-wear parts.

• Unique crafts ensures best feed quality: Constant clearance between cutters which ensures the appearance of the machine.

• New crafts reduce mechanical failures: smooth drive of the pelleting structure ensures stable operation and effectively reduces vibration and mechanical failures.

• Save time: it can prevent exchange die and cutter exchange quickly, save a lot of time for production.

• Safe and reliable: warning devices for door opening by mistake, which ensures operation safety.

• Feed quality improvement will bring true benefits to the customer.

• The feed production has high water resistance, which can effectively reduce feed waste and water pollution, benefits the digestion and absorption of aquatic animals and improve FCR.

Aqua Extruder Main Features

| Type | Main Power(kW) | Production Capacity(t/h) | |||

|---|---|---|---|---|---|

| SPHS 168F | SPHS 218F | SPHS 268F | SPHS 130×2 (twin-screw) | ||

| 160/200 | 250/315 | 400 | 280 (for small particles) | 315/355/400 | 315/355/400 |

| 4-7/5-9 | 7-12/8-15 | 10-20 | 2-5/ 0.8 Die hole(floating and sinking feed) | 9-14/ 3-8 Die hole(floating feed) | 7-9/ 3-8 Die hole(sinking feed) |